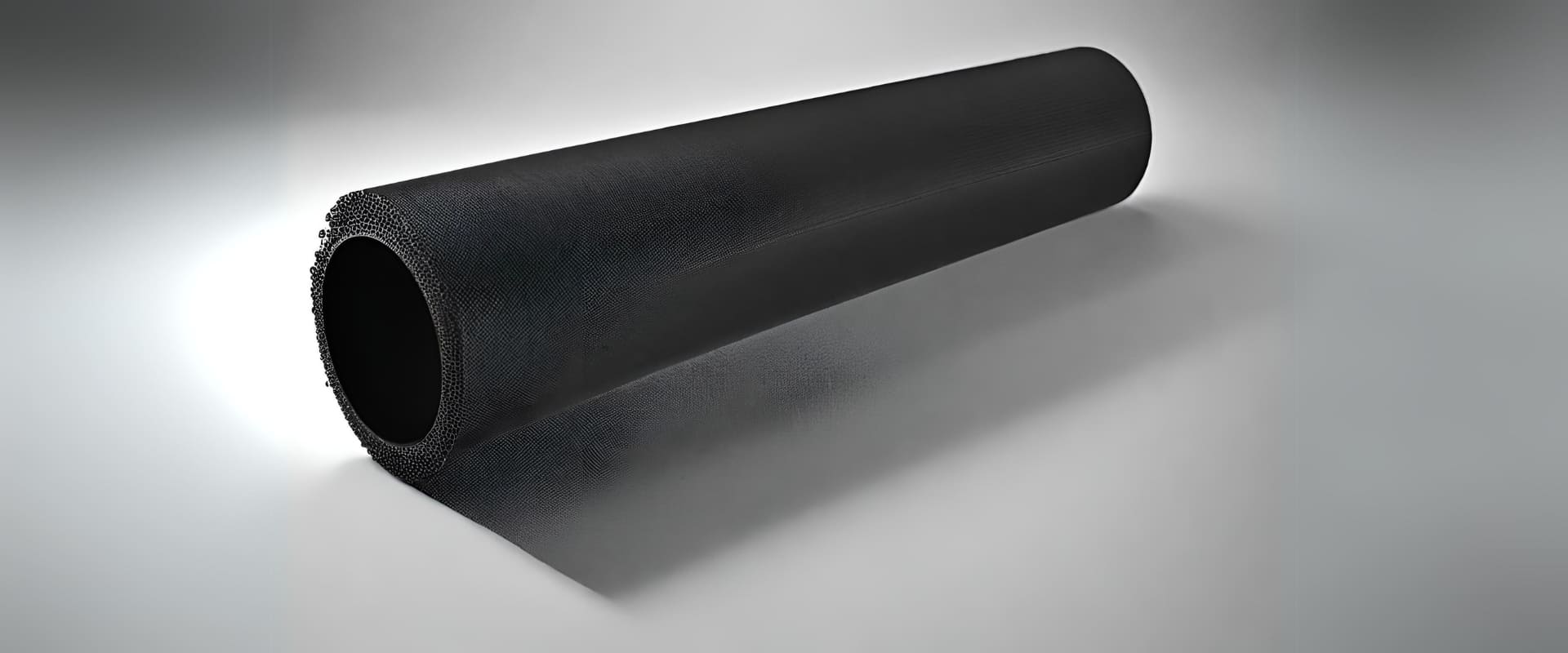

Carbon nanotube

hollow membranes

hollow membranes

Abstract

Carbon nanotube hollow membranes offer transformative potential in the chemical industry, particularly in selective gas separation and efficient liquid-phase processes such as nanofiltration and ultrafiltration. Ongoing research targets production challenges, aiming to facilitate widespread adoption and revolutionize chemical industry practices.

Blog

Carbon nanotube hollow membranes offer significant potential in chemical applications, particularly in separation, filtration, and catalysis. The nanoscale pores in these membranes enable selective gas separation, making them valuable in processes like natural gas purification and carbon capture. Their unique structure and high surface area also make carbon nanotube membranes ideal for catalysis, improving mass transfer and reaction efficiency in various chemical processes.

In liquid-phase separations, these membranes can be tailored for specific molecular properties, enhancing the efficiency of nanofiltration and ultrafiltration processes in the chemical industry. Additionally, the high sensitivity of carbon nanotubes to changes in their environment positions them as promising candidates for chemical sensing applications, with potential uses in industrial safety and environmental monitoring.

Despite their potential, challenges in large-scale production, cost-effectiveness, and long-term stability need addressing. Ongoing research aims to overcome these hurdles, paving the way for the widespread adoption of carbon nanotube hollow membranes in chemical processes. Their integration has the potential to transform traditional approaches to separation, catalysis, and sensing, offering more efficient, selective, and sustainable solutions in the chemical industry.

Furthermore, carbon nanotube hollow membranes have the capacity to revolutionize the chemical industry by addressing challenges related to liquid-phase separations and chemical sensing. Their ability to selectively filter molecules based on size, charge, and other specific properties holds great promise for advancing nanofiltration and ultrafiltration techniques. This can lead to improved purity and efficiency in various chemical processes, from pharmaceutical production to wastewater treatment. Additionally, the remarkable sensitivity of carbon nanotubes to changes in their surroundings enhances their utility in chemical sensing applications, offering precise and responsive detection capabilities for a wide range of chemicals. As research progresses to overcome production challenges, these membranes are poised to play a transformative role in enhancing the sustainability and efficiency of chemical processes across industries.

In conclusion, the agricultural application of hydrogels for water storage purposes represents a promising advancement in sustainable farming practices. By addressing water scarcity challenges, enhancing nutrient delivery, and promoting water-use efficiency, hydrogels contribute to the development of resilient and environmentally conscious agricultural systems. As technology continues to evolve, the integration of hydrogels into mainstream agricultural practices holds significant potential for ensuring food security and resource sustainability.

×

![]()

|

DOWNLOAD BROCHURE

|

|

REQUEST FOR QUOTATION

|