|

What We Do?

At M19 Lab, we're assisting various Oil & Gas manufacturers to ensure high quality products by providing access to advanced Oil & Gas testing products & services.

R&D Solutions

At M19, we understand that Oil & Gas manufacturers are facing increasingly complex issues from increasing regulatory compliances, performance sustainability & profits. We help you to meet these challenges by deploying our custom-designed Oil & Gas Lab Products.

|

Our Products

AI BASED | ULTRA - HIGH PRECISION | INDUSTRY SPECIFIC

|

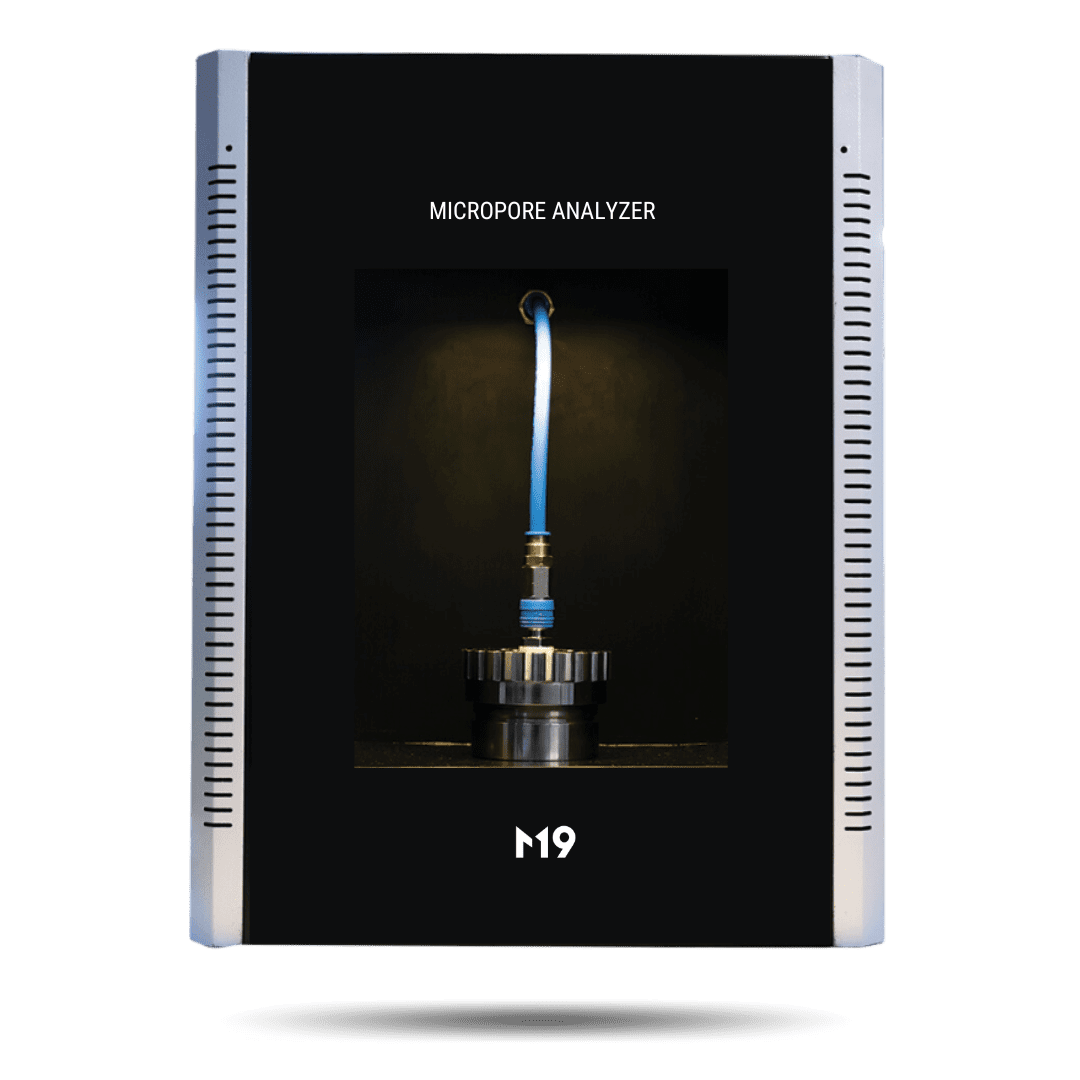

Micropore Analyzer

The advanced Micropore Analyzer (Model: MPA-100) with sophisticated technology, employing both Liquid Displacement and Capillary Flow Porometry, proves to be highly effective in evaluating the absolute/nominal micron rating, pore size distribution of a wide range of filters and membranes used in oil & gas application such as product filtration, pipeline filtration and terminal filtration. It is an indispensable tool which helps researchers and industrial professionals in selecting filters with suitable pore size for specific applications and separation needs.

ASTM F316, ASTM D6767

|

|

|

NanoPore Analyzer

The Nanopore Analyzer (Model: NPA-500) distinguishes itself as a state-of-the-art Pore Size Analyzer, equipped with remarkable capabilities. Its advanced technology, leveraging both Liquid Displacement and High Pressure Capillary Flow Porometry to determine absolute/nominal micron ratings, pore size distribution, for evaluating the performance of a wide range of filters such as high efficiency filters, membrane filters for the precise filtration. It is an indispensable tool which allows researchers and industrial professionals to select high-performance filters, maintain quality standards, and meet regulatory requirements in oil & gas exploration and production.

ASTM F316, ASTM D6767

|

|

Diffusional Permeability Analyzer

The Diffusional Permeability Analyzer (Model: DP-500) is an advanced instrument used to measure the permeability of membranes used in gas filtration/separation processes. These membranes selectively allow certain gasses to pass through while blocking others based on their permeation rates. By measuring the permeability of different gases, researchers can determine the selectivity of the membrane. This information is essential for designing and optimizing membranes for gas filtration/separation processes in gas purification and carbon capture.

ISO 15105-1, ASTM D1434, JIS K 7126, GB 1038

|

|

|

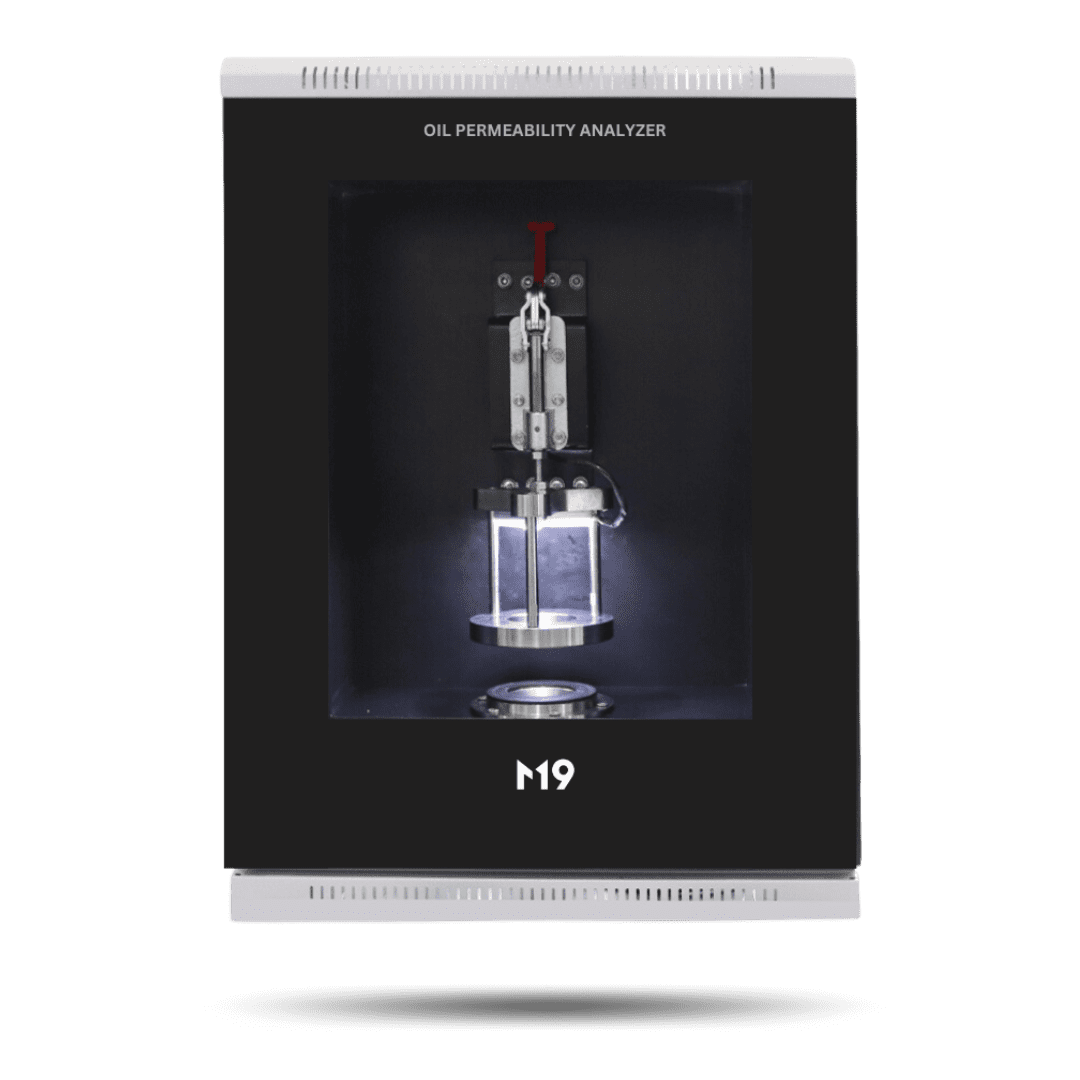

Oil Permeability Analyzer

The Oil Permeability Analyzer is a sophisticated instrument designed to measure the rate at which oil passes through samples under controlled conditions. By a constant pressure difference across the specimen and measuring the flow of oil, the oil permeability of the sample can be calculated. This method provides accurate and reliable data on oil permeation characteristics, essential for assessing the performance of various oil filters. By providing accurate measurements of oil permeability, this analyzer contributes to improving efficiency, safety, and sustainability across different stages of oil exploration, production, and processing.

REF. ISO 7231:2023, REF. ASTM F778

|

|

|

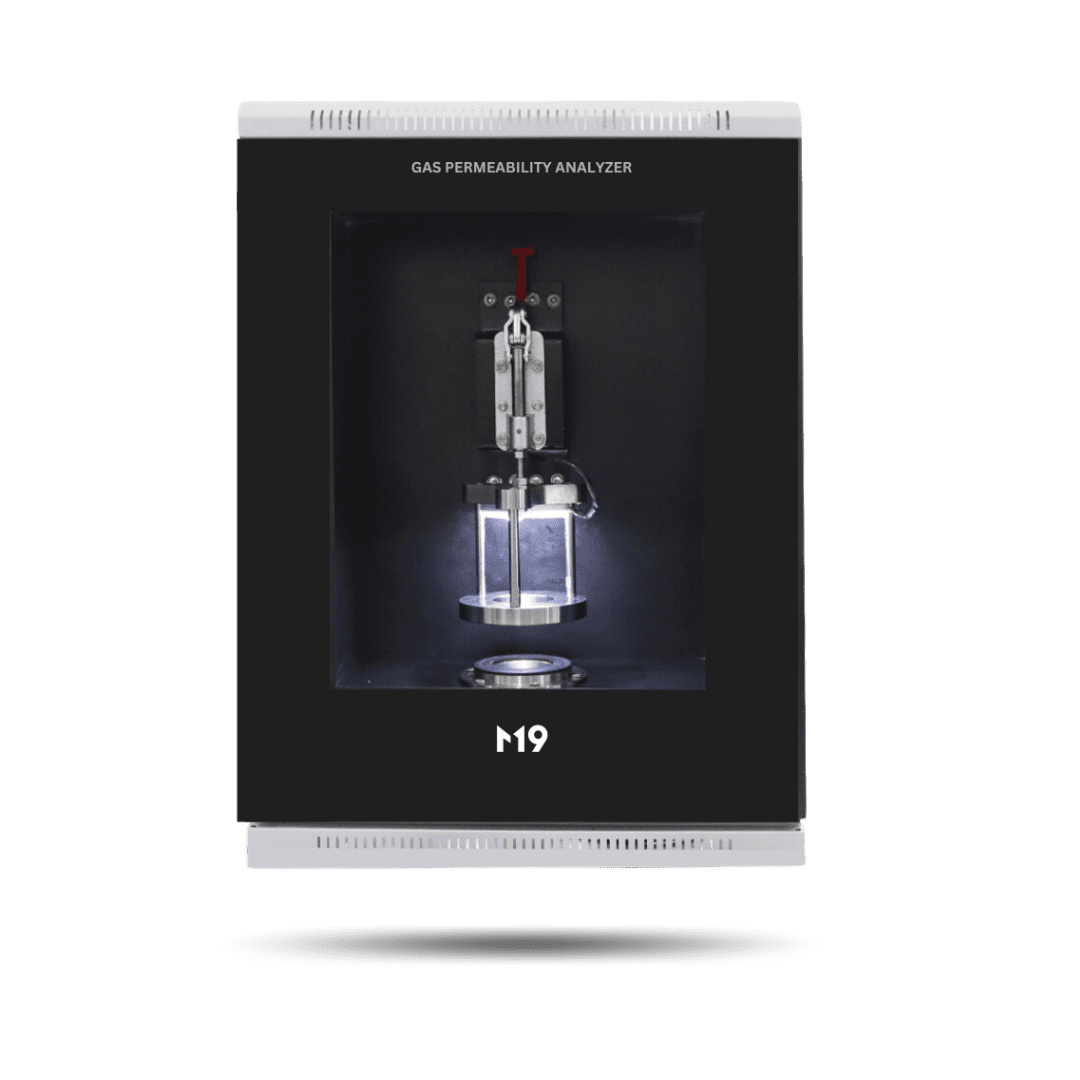

Gas Permeability Analyzer

The Gas Permeability Analyzer (Model: GP-100) is a sophisticated instrument designed to measure the rate at which gasses pass through samples under controlled conditions. In the oil & gas industry, the GP-100 is essential for evaluating the permeability of various materials such as membranes and filters. By providing accurate measurements of gas permeability, our GP-100 contributes to improving efficiency, safety, and sustainability across different stages of oil & gas exploration, production, and processing.

ASTM D737-18, ISO 9237, ASTM F778

|

|

|

Density/Porosity Analyzer

The Density/Porosity Analyzer, also known as Helium Pycnometer is an scientific instrument specifically designed to measure the true density and porosity of various materials such as petroleum coke, solid pitch, reservoir rocks etc. This analyzer plays a crucial role in various aspects of oil & gas exploration, production, and refining, helping to optimize processes and improve efficiency. By accurately measuring the true density and porosity, researchers can ensure the physical characteristics of a wide range of materials, helping in reservoir evaluation and production operations.

ISO 12154, ASTM D2638, ASTM D4892

|

|

|

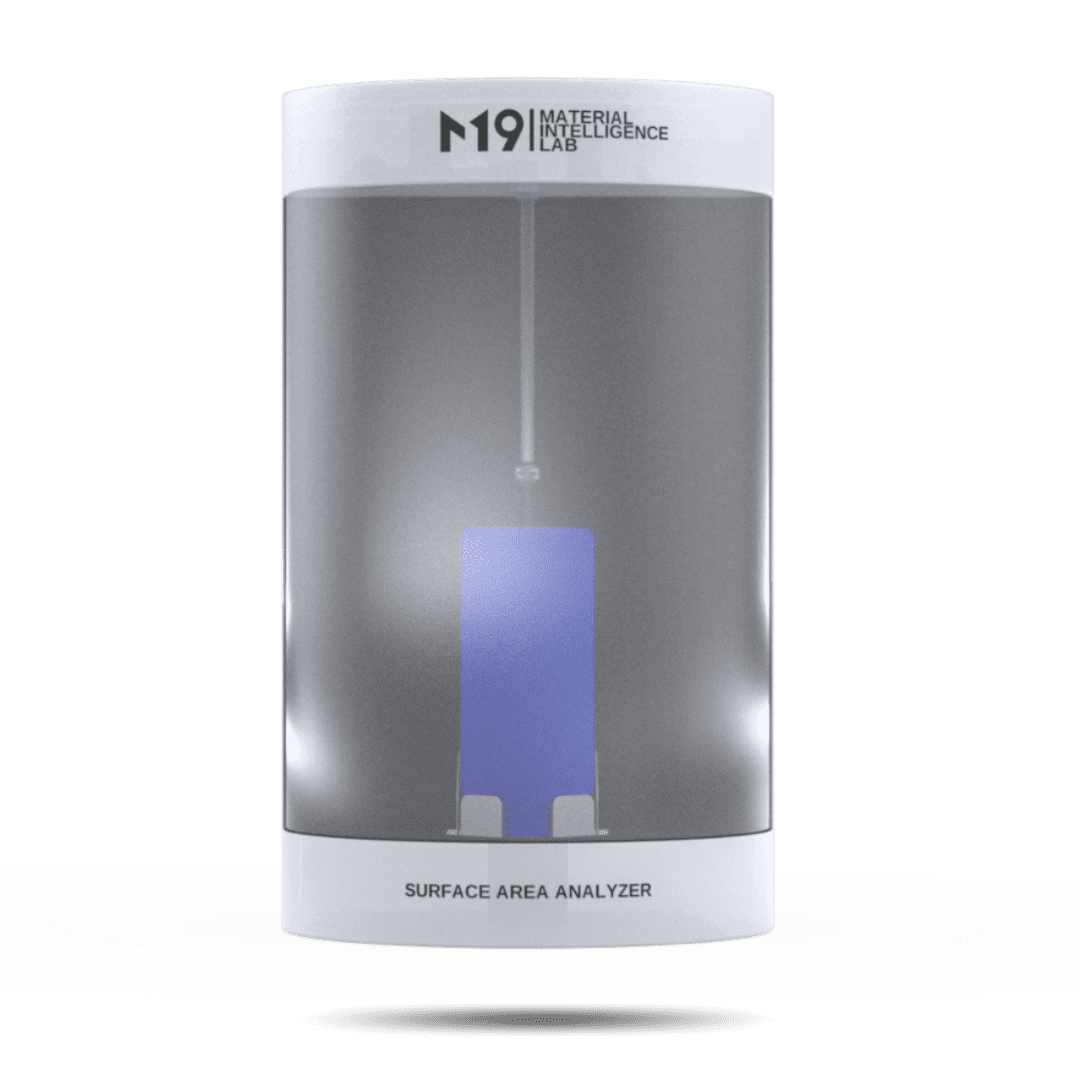

Surface Area Analyzer

Surface Area Analyzer, also known as a Gas Adsorption Analyzer is indispensable in the oil & gas industry for characterizing catalysts, adsorbents and other porous materials. They provide key information such as specific surface area, pore size distribution, and adsorption behavior of sample material. This data is crucial for optimizing processes, ensuring quality control, and developing new materials for various applications in oil & gas production and refining processes.

ISO 9277, ASTM D4641-15, ASTM D3663-20, ASTM D4635-19

|

|

|

Particulate Filtration Efficiency Analyzer

Particulate Filtration Efficiency Analyzer (Model: PFE-50) plays a crucial role in the oil & gas industry by ensuring the effectiveness of various filters used to remove particulate contaminants from various fluids and gasses. PFE-50 helps in assessing the performance of oil filtration systems, thereby protecting critical equipment from damage and minimizing downtime and maintenance costs. By analyzing the performance data provided by PFE-50, operators can fine-tune filtration parameters and improve overall process efficiency and productivity.

ISO 29463, ISO 14644

|

|

APPLICATIONS

Automotive Filters

Automotive Filters are a type of Oil Filter used in automobiles to remove contaminants from engine oil. They are typically made up of a metal housing with a replaceable filter element inside. Automotive Filters can be designed to remove a wide range of contaminants from engine oil, including dirt, dust, and other solid particles. They can also be designed to remove water or other types of contaminants from the oil.

Cartridge Filters

Cartridge Filters are commonly used in Oil Filtration applications to remove contaminants from oil. They are made up of a cylindrical housing with a filter element inside. The filter element is typically made of a pleated paper or synthetic material that traps contaminants as the oil flows through it.

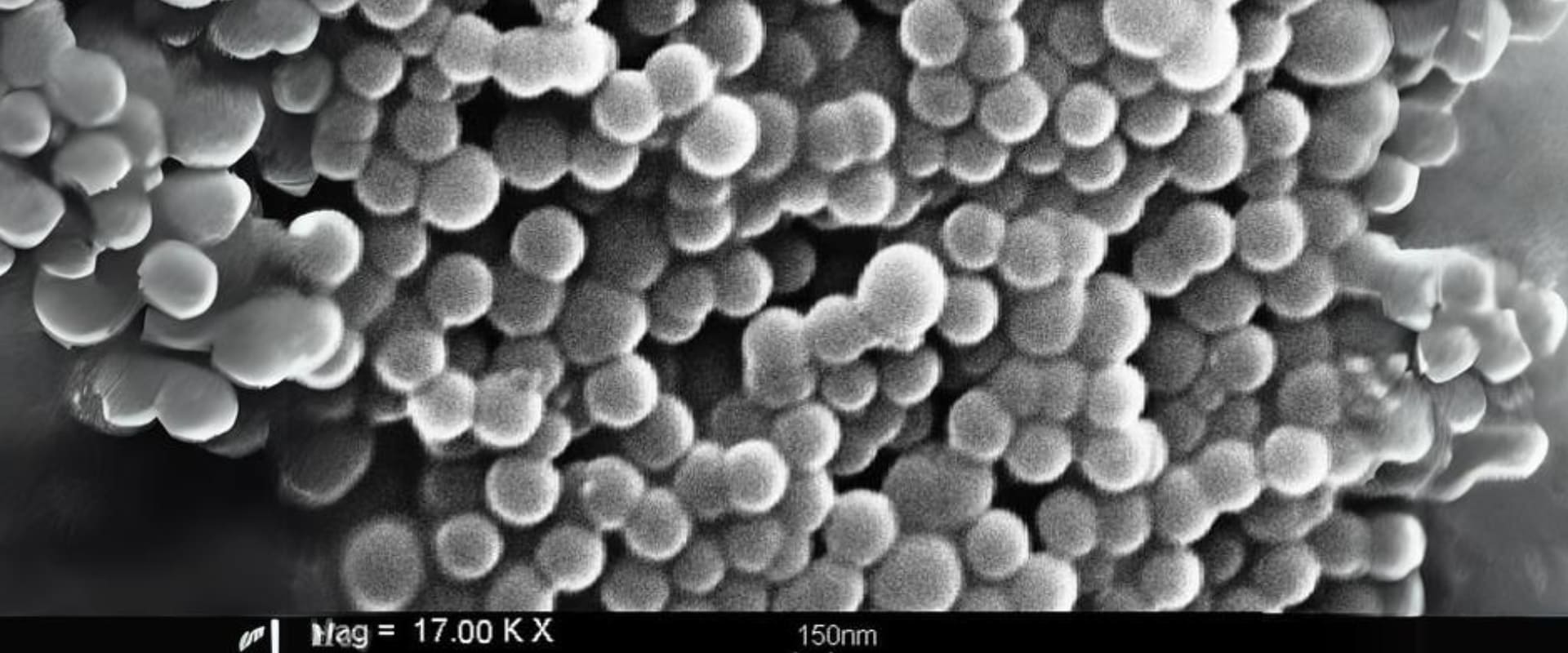

Sintered Metal Filters

Sintered Metal Filters are also commonly used in Oil Filtration applications to remove contaminants from oil. In this application, the filter is made by compressing Metal Powder into a solid block and then sintering it at high temperatures to create a porous structure. The oil flows through the porous structure, while contaminants are trapped on the surface or inside the filter.