Abstract

Silica nanoparticle modification enhances polysulfone and polypropylene membranes, improving mechanical strength, thermal stability, and hydrophilicity. These membranes show promise in water treatment, desalination, and industrial separations, with ongoing research aiming to customize parameters for specific applications, advancing sustainable membrane technologies.

Blog

Silica nanoparticle modification of polysulfone (PS) or polypropylene (PP) membranes is a notable advancement in membrane technology, offering enhanced properties for various filtration applications. The incorporation of silica nanoparticles into polymer membranes introduces desirable features such as improved mechanical strength, thermal stability, and surface characteristics. This modification is particularly beneficial in addressing challenges related to fouling, permeability, and selectivity, making these membranes promising candidates for applications in water treatment, desalination, and other separation processes.

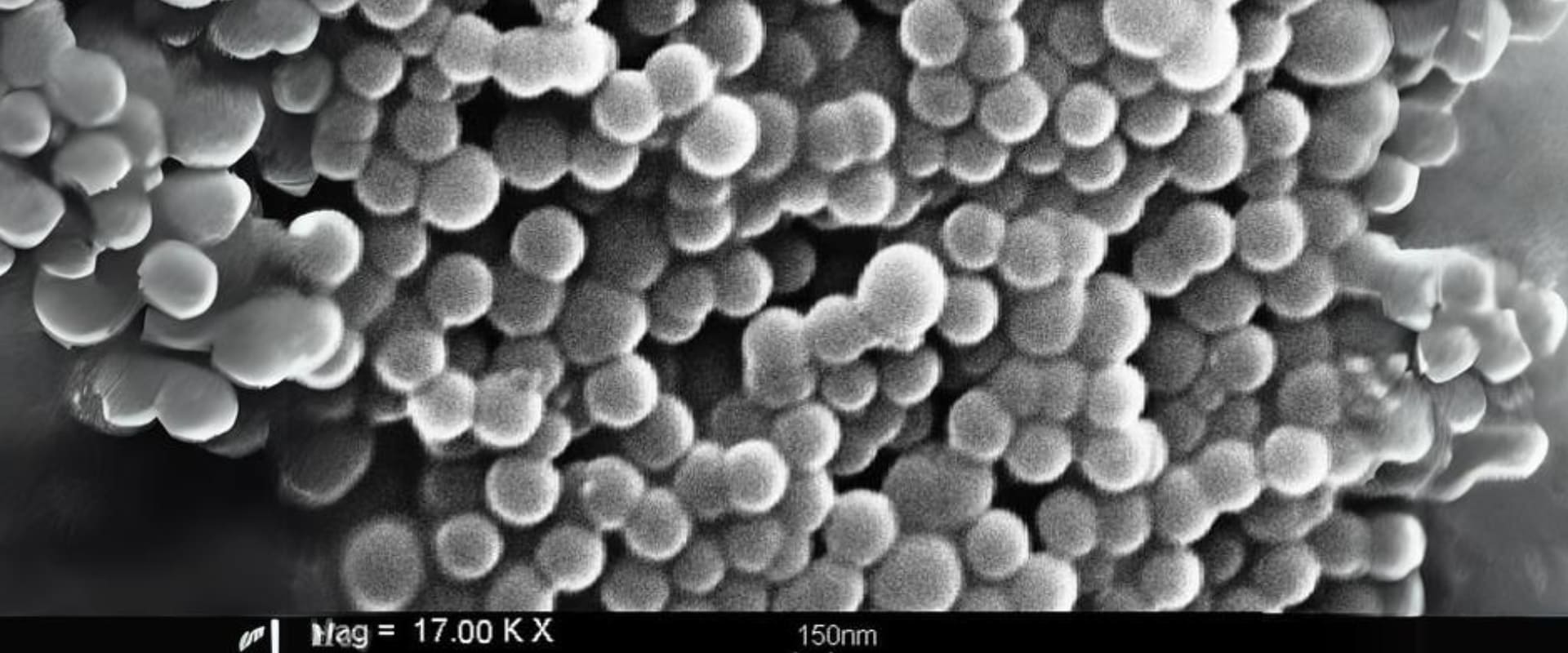

The addition of silica nanoparticles to the polymer matrix contributes to the formation of a composite membrane with a unique structure. Silica, known for its high surface area and chemical inertness, enhances the membrane's hydrophilicity, rendering it more resistant to fouling by preventing the adhesion of contaminants and organic substances. The increased hydrophilicity can also lead to improved water permeability, making these membranes efficient in water treatment applications where high flux rates are desirable.

The mechanical properties of the membrane are strengthened through the incorporation of silica nanoparticles, resulting in enhanced durability and resistance to physical stresses. This is particularly advantageous for applications requiring long-term and continuous operation, such as in wastewater treatment plants. Additionally, the thermal stability of these composite membranes is improved, widening the range of operating temperatures and making them suitable for diverse industrial settings.

Researchers continue to explore the specific effects of varying silica nanoparticle concentrations and sizes on membrane performance. Fine-tuning these parameters allows for the customization of membranes to meet the requirements of specific separation processes. As the understanding of the interaction between silica nanoparticles and polymer matrices deepens, the potential applications of these composite membranes in critical processes, including water purification and industrial separations, are expected to expand, contributing to the advancement of sustainable and efficient membrane technologies.