|

What We Do?

At M19 Lab, we're assisting various Government manufacturers to ensure high quality products by providing access to advanced Government testing products & services.

R&D Solutions

At M19, we understand that Government manufacturers are facing increasingly complex issues from increasing regulatory compliances, performance sustainability & profits. We help you to meet these challenges by deploying our custom-designed Government Lab Products.

Our Products

AI BASED | ULTRA - HIGH PRECISION | INDUSTRY SPECIFIC

|

Density/Porosity Analyzer

The novel Density Analyzer also known as Helium-Pycnometer provides users with real time data of true Density of specimens. It works on the Principle of Gas expansion based on Boyle’s Law of Isothermal Process. The actual volume of the sample is evaluated which further is then used to calculate Density.

ASTM B923-10, ASTM C110-15

|

|

|

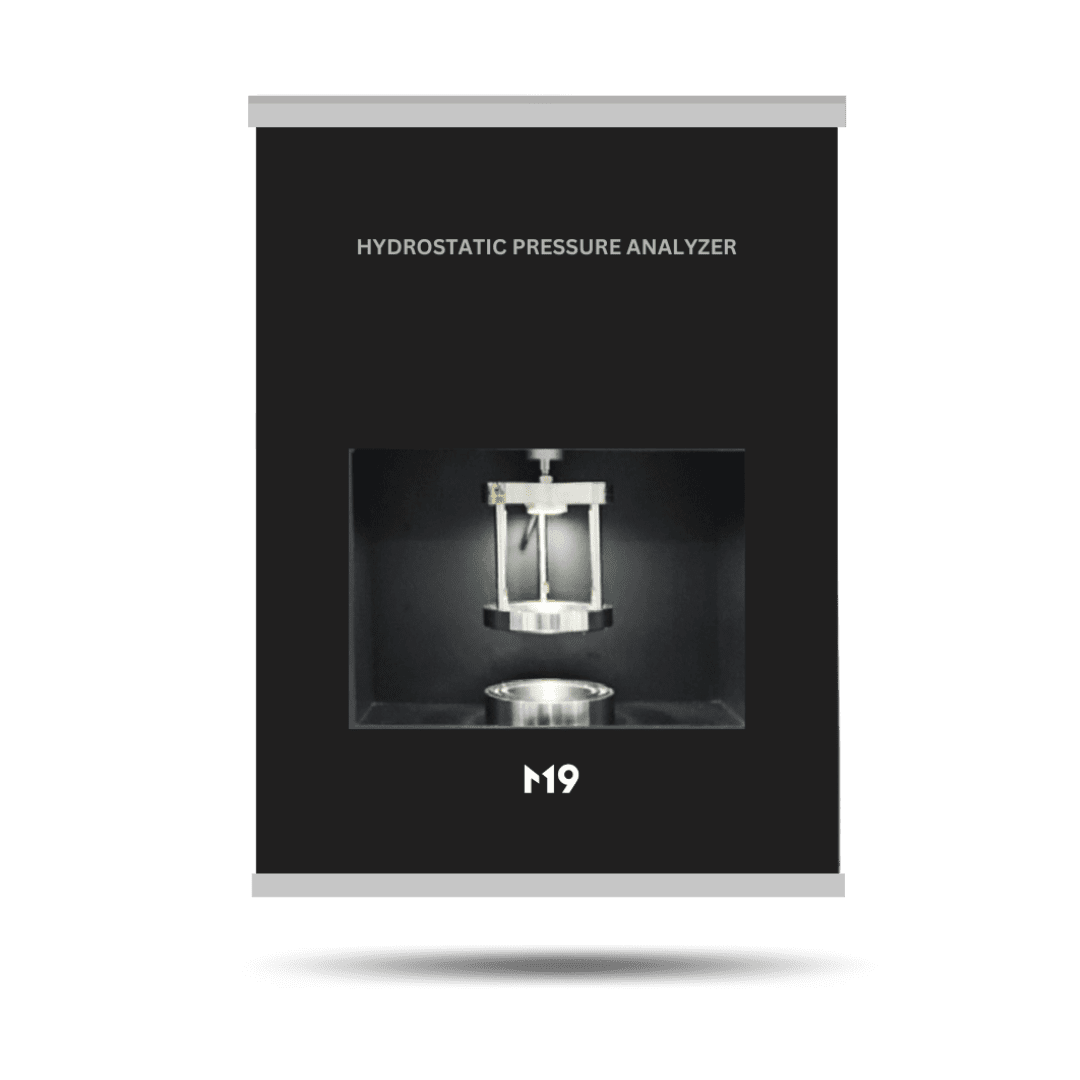

Hydrostatic Pressure Analyzer

HPA-50 is a device designed to evaluate a fabric's ability to resist the penetration of water under Hydrostatic Pressure, taking into account factors such as yarn, weave, and surface finish. This is achieved through an automated control system that applies either static or dynamic force, incrementally increasing until at least 3 points of leakage are detected.

AATCC127

|

|

|

NanoPore Analyzer

The Nanopore Analyzer (NPA-500) device stands out as a cutting-edge pore size analyzer, offering remarkable capabilities. Its advanced technology relies on both liquid displacement and capillary flow porometry, making it highly efficient in characterizing the pore sizes of coated/laminated fabrics. The device is specifically tailored for the nanoporous media, making it an ideal choice for evaluating the performance of coated media and provide accurate and detailed insights into fabric's pore structure.

ASTM F316, ASTM D6767

|

|

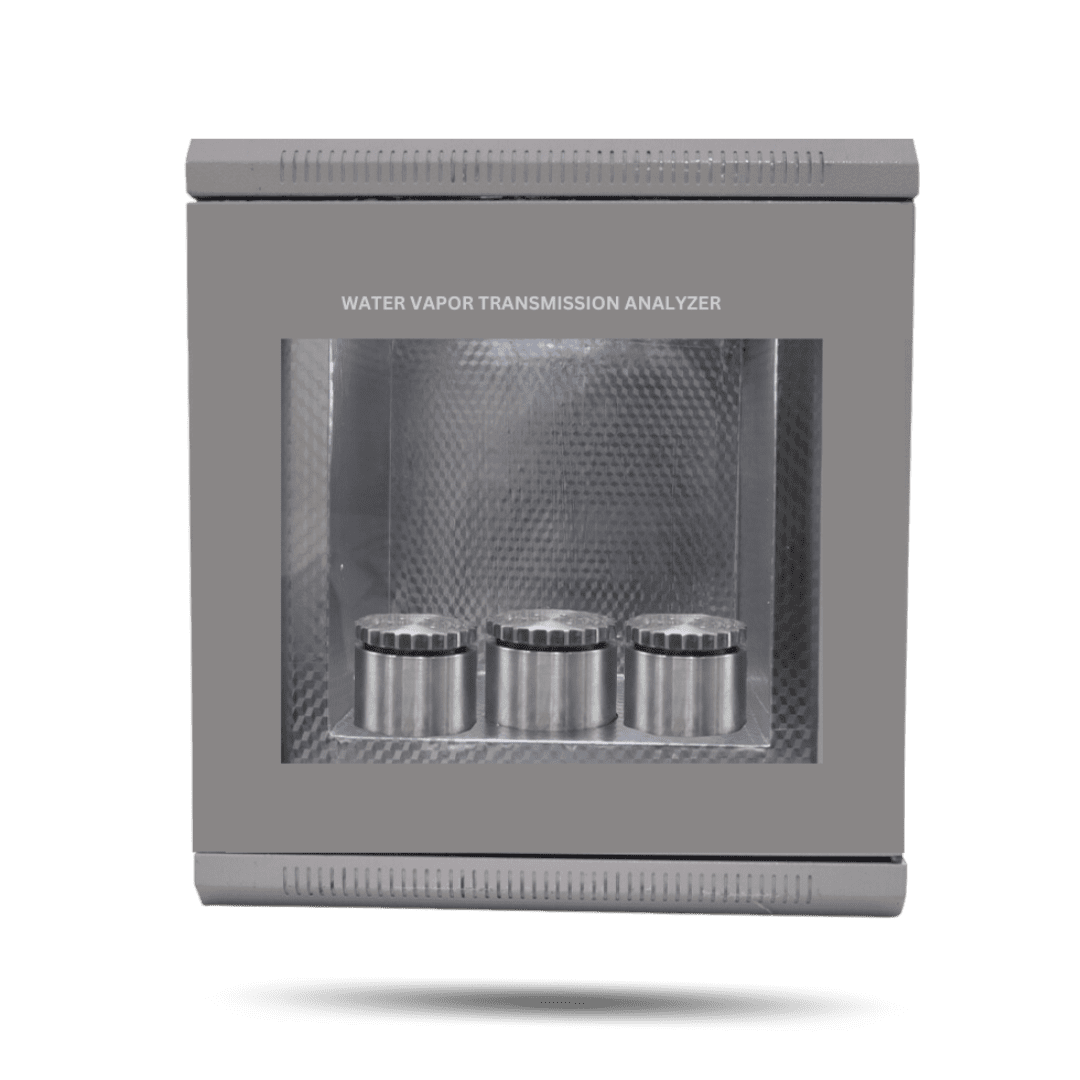

Water Vapor Transmission Analyzer

The WVTR (Water Vapor Transmission Analyzer) is a specialized device created and produced to assess the Water Vapor Transmission Rate, Permeance, and Permeability of fabrics or flat barrier elements. Its purpose is to measure how Water Vapor travels through a material. The evaluation of WVTR is crucial in industries where moisture plays a significant role. M19 provides a standardized procedure that aligns with ASTM standards and meets industry requirements.

ASTM D737, ASTM F778

|

|

|

Filtration Efficiency Analyzer

The FEA-50 is a device designed to evaluate a fabric's ability to resist the penetration of particulate matter, taking into account factors such as yarn, weave, and surface finish. This is achieved through an automated Aerosol Control System that applies either mono or poly dispersed particles to one side of the fabric, and the particle counts in the upstream and downstream, along with differential pressure are detected.

ASTM F2100

|

|