Abstract

Dye contamination in industrial waste water demands advanced solutions. Membrane technology, a sustainable and efficient approach, acts as specialized filters to selectively remove dye molecules. Versatile and scalable, it addresses complexities in industrial waste water treatment, aligning with sustainability goals. As industries prioritize environmental stewardship, the integration of membrane technology stands as progress in safeguarding water resources from dye contamination.

Blog

The issue of dye contamination in wastewater poses a significant environmental challenge, necessitating innovative solutions for effective remediation. Waste water from various industrial sources, including textile factories, food processing, paper and printing products manufacturing, as well as vehicle production, often carries a diverse array of dye pollutants. Addressing this concern requires advanced and efficient techniques, with membrane technology emerging as a promising solution for the removal of dyes from wastewater.

The widespread use of dyes in industrial processes has led to their pervasive presence in wastewater, posing a threat to aquatic ecosystems and human health. Textile factories, known for their intensive use of dyes in fabric coloring and treatment, contribute substantially to this environmental problem. Similarly, industries involved in food production, paper manufacturing, and vehicle production also discharge waste water containing various dye compounds, further exacerbating the contamination issue.

Traditionally, diverse methods have been employed for the removal of dyes from wastewater, and among these, adsorption has been a commonly utilized approach. However, as environmental challenges evolve and stringent regulations are implemented, there is a growing demand for more efficient and sustainable solutions. Membrane technology, a cutting-edge approach, has gained prominence for its capacity to provide effective dye removal from wastewater, offering advantages over traditional methods.

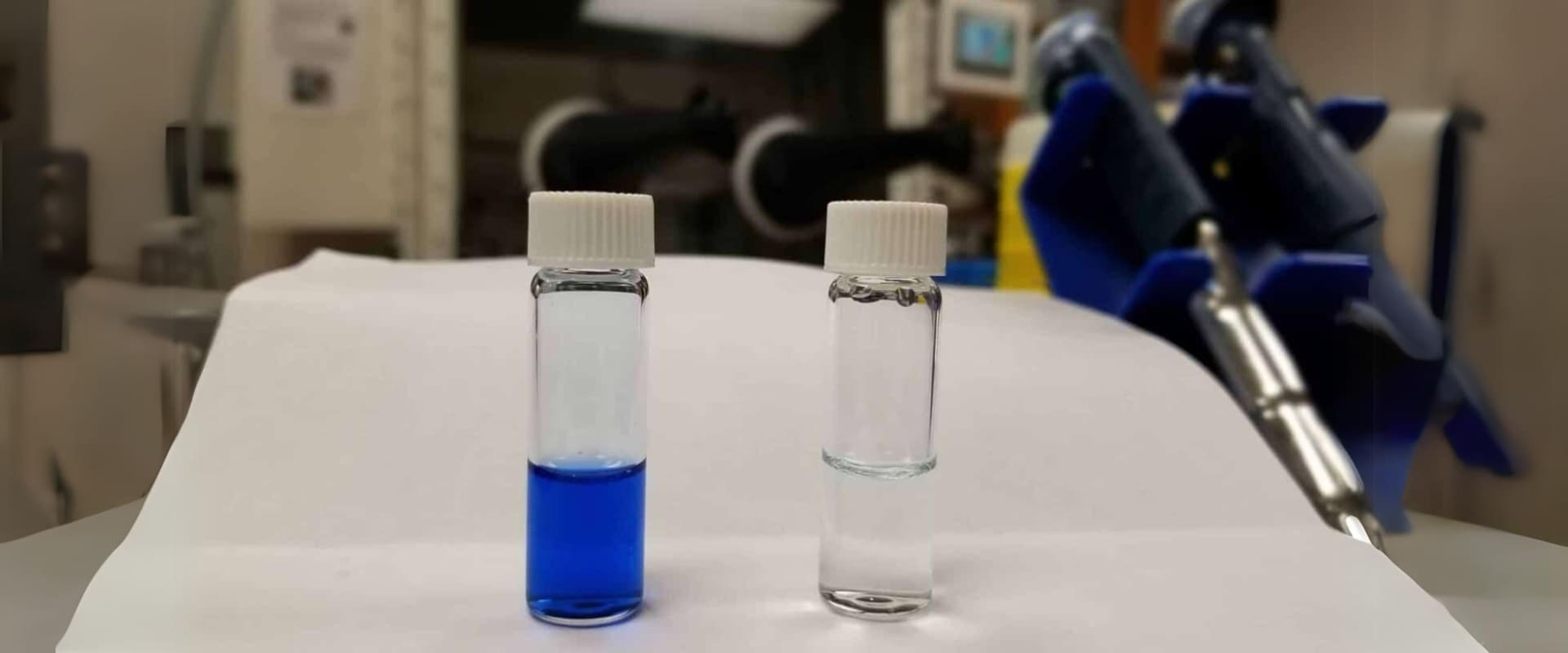

Membrane technology involves the use of semi-permeable barriers that selectively allow the passage of certain substances while blocking others. In the context of dye removal, membranes act as specialized filters, allowing the separation and collection of dye molecules from the waste water. This process is particularly effective in capturing dye particles, preventing their discharge into natural water bodies and mitigating the potential harm to aquatic life.

One of the key advantages of membrane technology is its versatility, allowing customization based on the specific characteristics of the dye pollutants and the wastewater composition. Different membrane materials and configurations can be employed to target a wide range of dye compounds, ensuring the effectiveness of the removal process. Moreover, membrane technology offers scalability, making it suitable for applications ranging from small-scale industrial operations to large wastewater treatment plants.

The implementation of membrane technology for dye removal aligns with the broader goals of sustainable water management and environmental protection. By employing advanced membrane filtration systems, industries can not only meet regulatory standards but also contribute to the preservation of water quality and ecosystem health. This innovative approach represents a step forward in addressing the complexities of industrial waste water treatment, providing a reliable and efficient means to combat dye contamination and its associated environmental impacts.

In conclusion, the contamination of waste water with dyes from various industrial sources necessitates the adoption of advanced technologies for effective remediation. Membrane technology, with its versatility and efficiency, emerges as a promising solution for the removal of dye pollutants, offering a sustainable approach to address the environmental challenges associated with industrial waste water discharge. As industries continue to prioritize environmental stewardship, the integration of membrane technology in waste water treatment processes stands as a beacon of progress in safeguarding water resources and ecosystems.